Material Handling is the movement, protection, storage and control of materials & products throughout manufacturing, warehousing & distribution centers.

Material Handling Storage Systems help optimize the flow of materials through your warehouse reducing wasted space & increasing profitability. Choosing the right type of storage system will depend on the physical size and weight of the items to be stored as well as the frequency of use. Designing the configuration of the storage system also depends on the items’ quantities and characteristics, as well as the types of equipment that will be needed to move them to and from storage.

Shelving with flow racks, bin boxes, totes, modular drawers, high density mobile systems & automated systems like vertical carousels/lifts all expand the productivity inside warehouses. Add more storage space by installing shelving mezzanines for multi-level storage benefits.

We specialize in designing warehouse systems that will increase warehouse efficiency and maximize productivity.

To get started creating a custom storage solution for your business, contact our experts today!

High Density Storage Systems

With High Density Mobile Storage Systems, getting the most out of your space is a key consideration. By mounting shelving units on movable carriages, this system eliminates the need for multiple aisles.

Retain your capital investment and allow flexible growing strategy with our upgradable high-density multi-tier mobile grow racks system. Our vertical growing solutions will provide for a more organized facility that will increase workflow, production, and profits.

You can utilize your existing shelving or storage cabinets with the High Density System or select from a wide range of storage options.

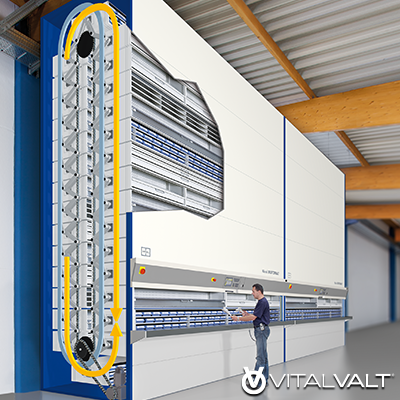

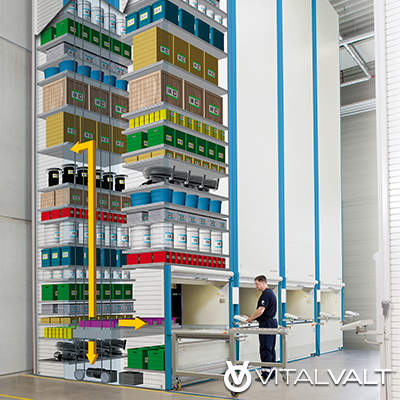

Vertical Storage Systems

Vertical Storage Systems allows 60% or more storage capacity to be accommodated on minimal floor space by making use of the available room height.

These storage systems bring the requested item to the retrieval point at the touch of a button in just a few seconds. This means no distances to walk or ladders to climb when looking for parts or returning them after use.

We design the carrier interior to accommodate the most varied of tasks within production systems and warehouse requirements. Both shelves and mechanical parts are designed to match the size and weight of the storage material. It is this flexibility which makes these systems so economical.

Shelving

No matter what specific requirements your warehouse demands, we have a shelving solution for you:

Shelving Accessories

When everything in your warehouse has a place, you are primed for efficient, cost-effective performance. For everything that doesn’t require special storage, we offer these simple accessories:

- Bins

- Open or Closed Backs & Sides

- Pick Modules

- Doors

- Drawers/Dividers

- Gravity Flow Racks

Our experienced Sales Team and CAD Design department can create a custom layout

targeting your specific needs with a comprehensive quote for the

storage system to suit your business.